While our focus is on aircraft-certified mission equipment racks, we continue to receive requests for ground station equipment. The 40U rack below is our first example of a cost-competitive, shock-isolated rack for installation in a ground vehicle subject to Mil-Std-810G

Quad Operator Consoles Delivered

The first production units of our new Quad Operator Console. Designed to accommodate four operators at a single workstation on a Dash 8. The "Quad" gives each operator dual 21in monitors with an assembly weight of 91lbs.

VMR + Monitor Bezel

A new product for the new year. This is our new pared-down console design targeted at ISR or aerial mapping customers. The bezel can accommodate a 17in or 21in monitor and provides some dzus space.

The console is sitting on top of our Vertical Mission Rack (VMR) which provides 7U of rack space rotated 90 degrees. This allows for the rack to keep a clear aisle in aircraft such as the King Air.

CMR and Console - King Air Installation

Our first Core Mission Rack (CMR) with a new console design was was installed in a King Air 90-series over the weekend in California. This design provides dual 21" monitors, an integral keyboard, and bolts into a King Air with just four Ancra studs. Integration work was done by Aevex Aerospace and includes their GeoFOCIS system and custom power distribution unit. The installation pictured below also includes a 12" Dzus form-factor module.

This system is design to fit in any King Air, C208, PC-12, Cessna 404, and many other small turboprops.

Successful Pull Test

Our team at Helios had an exciting end to last week. We successfully pull tested one our 14U equipment racks (HE15-A001). These racks will be installed on the Army's ARL-E (Airborne Reconnaissance Aircraft) .

The rack was pull tested to 3,442lbs. There was no permanent deformation or buckling under the ultimate load with good correlation to the FEM.

Challenger Rack + Console

Helios delivered our first set of racks + consoles to a customer operating a Bombardier Challenger. The setup pictured below consists of 3 modules: a 14U, a 10U, and a bolt-on console module. The console module houses dual 24” monitors and an integral keyboard with pointing device. The options Dzus module pictured below houses up to 24” of dzus form-factor components.

Vertical Mission Rack Delivery

Helios delivered a Vertical Mission Rack (VMR) to an airborne LiDAR operator on US Army Airworthiness Release. The VMR houses 7U of rack space and is the same width as a King Air “riser”—so it doesn’t block the aisle. The VMR installs via (4) Ancra fasteners, and can be expanded to include ASO tables, monitor mounts, or other stacked equipment. It is certified for 200 lbs of internal payload and up to 75 lbs attached to the top-mounted seat tracks. Contact us today for an interface control drawing to see how the VMR can help fit more equipment in your King Air without sacrificing aisle space.

Gen2 Core Mission Rack Delivery

Helios delivered the first of our second-generation Core Mission Racks (CMR) to a bathymetric LiDAR operator this week. This customer has already fielded eight first-gen CMRs, so we’re excited to hear feedback on the new product. The revised CMR is 5 lbs lighter, stiffer, and has several usability improvements from an integration standpoint. The new CMR is backwards compatible with all fielded modules, and is drop-in-ready for a King Air, PC-12, Caravan, and many more.

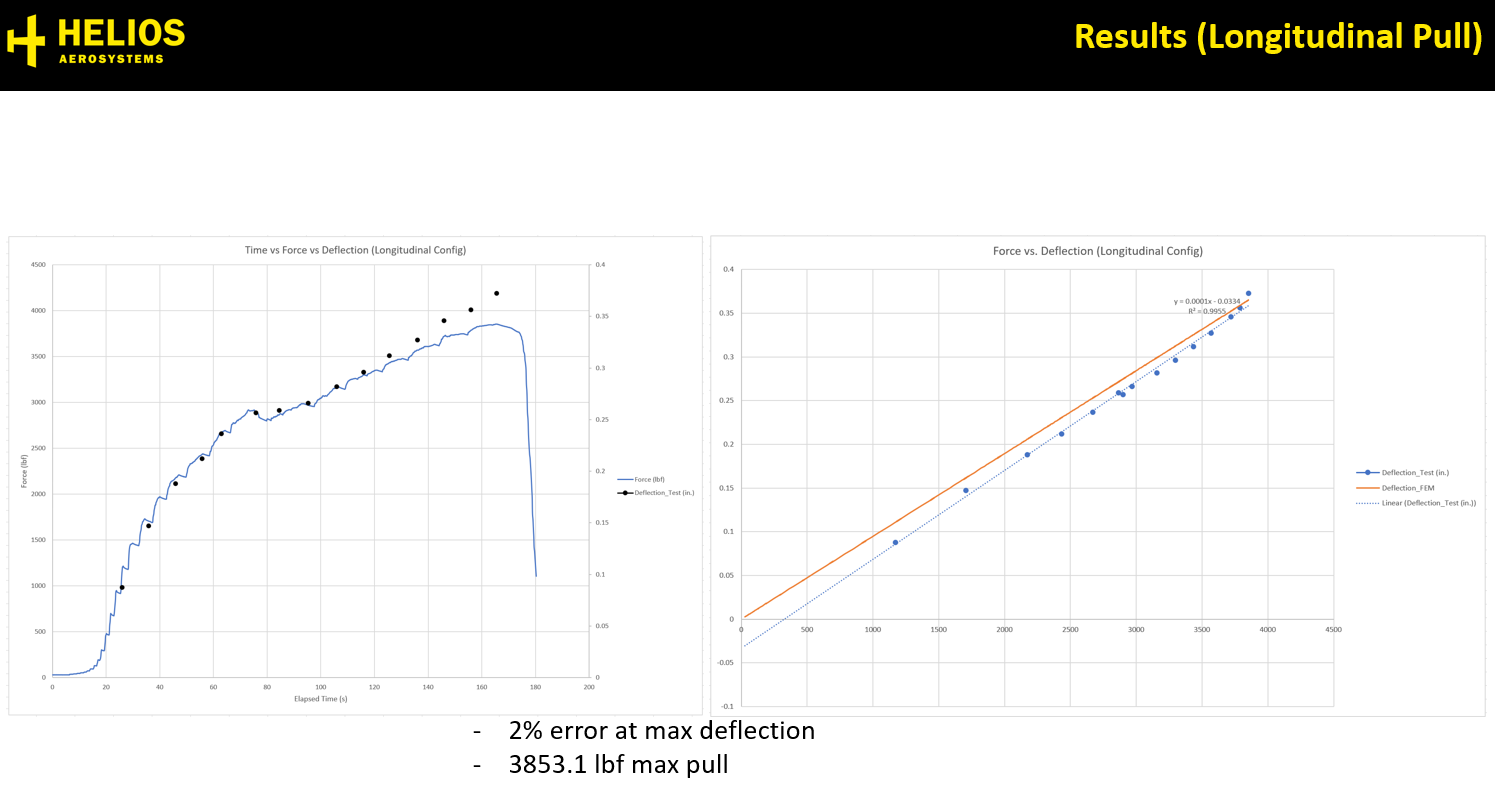

Successful Pull Test of Helios Stackable Rack System

Helios successfully completed a 9G pull test of our Helios Stackable Rack System (HSR) today. The test pulled the HSR in 2 axes to the 9G Ultimate Load for the system and measured deflection and force. While all Helios products are substantiated via analysis, pull testing is an important part of validating these results and ensuring safety of our fielded systems.

Our pull test frame will allow rapid testing and evaluation of future products as needs arise. It is fully NIST calibrated and capable of pulling up to 10,000 lbf.

DHC-8 Stackable Rack Shipset - Fielded

A shipset of eight Helios Stackable Rack (HSR) modules has completed operational test and evaluation and was fielded this week in support of a US DoD end customer. The 14U modules stack 2 units high in the DHC-8-315, and they house up to 400 lbs of equipment per stack. The modular nature of the HSR allows for rapid integration, flexibility for non-rack-mounted equipment, and easy access to both sides of the LRUs.

Gen2 Operator Console - International LiDAR Mapping Forum

Helios will be at the International LiDAR Mapping Forum, in Denver, next week. We’ll have a prototype of our second-generation mission console on display.

Below is a picture of the prototype, and the YouTube link explains some of the unique features. The setup pictured below will fit in a King Air, and can accommodate a wide range of monitor options. The stacked configuration pictured is 2, 21.5” monitors.

Helios Stackable Rack System - First Delivery

The first delivery of the Helios Stackable Rack System occurred in late November, 2018. This system consists of 6U and 14U modules that can stack 2-high in any order. The system can be longitudinal or transverse-mounted, and can fit in many aircraft types.

Pictured below is a stack of (2) 14U modules being test fit in the aft cargo area of a DeHavilland Dash 8. Each 14U module, in this configuration, can be loaded with 200 lbs. of payload. Both modules are weight-optimized, have integral carrying handles, and replaceable mounting rails.

The picture below shows a 14U+6U stack, mounted in a King Air 200. This configuration uses the top 6U module to house pullout monitors and other operator-facing equipment.

24U Racks Delivered

This week we delivered four, 24-U racks for use in an R&D program on a DC-3. Because of the large cabin size, we were able to design a single rack module that is quite a bit deeper and taller than our usual base rack unit.

This variant of the rack implements many of the same features: note the seat track segments in each corner to be used with lifting shackles or equipment mounting, integral handles, and the modular floor plate. We also have a flip-down keyboard tray design for when and if the requirement arises. This design may prove to be a good back-of-the-aircraft, standard electronics rack, to be used in conjunction with a cabin-mounted operator rack.

Pelican Case Fit Check

We received our first Pelican Case for fit-check on the rack module. The fit accommodates approximately 2 inches for padding around all sides of the rack and can be used to ship either empty or populated racks.

Cases can be ordered in a variety of colors and features, and are approximately 4-week lead (though we will stock a few). The case pictured below is a Model AL2825-1612AC/HL in Gray.

Dual Rack Config Delivery - F406/Cessna 404

The first side-by-side configuration has been delivered to a GIS firm supporting a US Army Corps of Engineers project. These racks will be populated with Optech and Leica Bathymetric LiDAR mapping equipment, and will operate in a Riems F406 over US coastlines, mapping silt deposits.

Note the addition of the tabbed cutouts on the shear walls. These will be used to route cooling tubing (and possibly fans) to specific areas requiring more airflow.

First Operational Deployment

Helios Operator Rack, Unit 1 completed flight testing in July and is currently the first unit deployed in support of a US DoD multi-mission aircraft. The configuration is pictured below, and houses a Viewpoint 21.5" quad mode monitor along with a smaller auxiliary monitor for continuous view of multiple feeds.

The unit accommodates a full-size keyboard and mouse in the folding keyboard tray. For easy access, the comms package is mounted to a sandwich-panel shelf on top of the rack (behind the console).

First GIS Operator

The first two racks for a commercial GIS operator are currently in fabrication. The installation will go in a Reims F406, and will consist of two racks in side-by-side arrangement at the far aft end of the cabin. The racks will house LRUs associated with a bathymetric sensor (Optech CZMIL), and several other systems.

Installation is scheduled for early October, with photos to follow.

First Rack Fabrication - Complete

Conformity inspection is complete on Helios Operator Rack S/N 001. This unit will go in a 200-series King Air in a multi-mission/ISR Role.